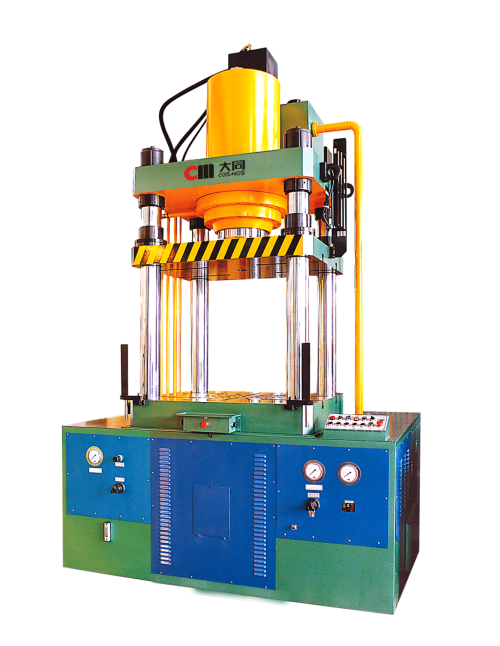

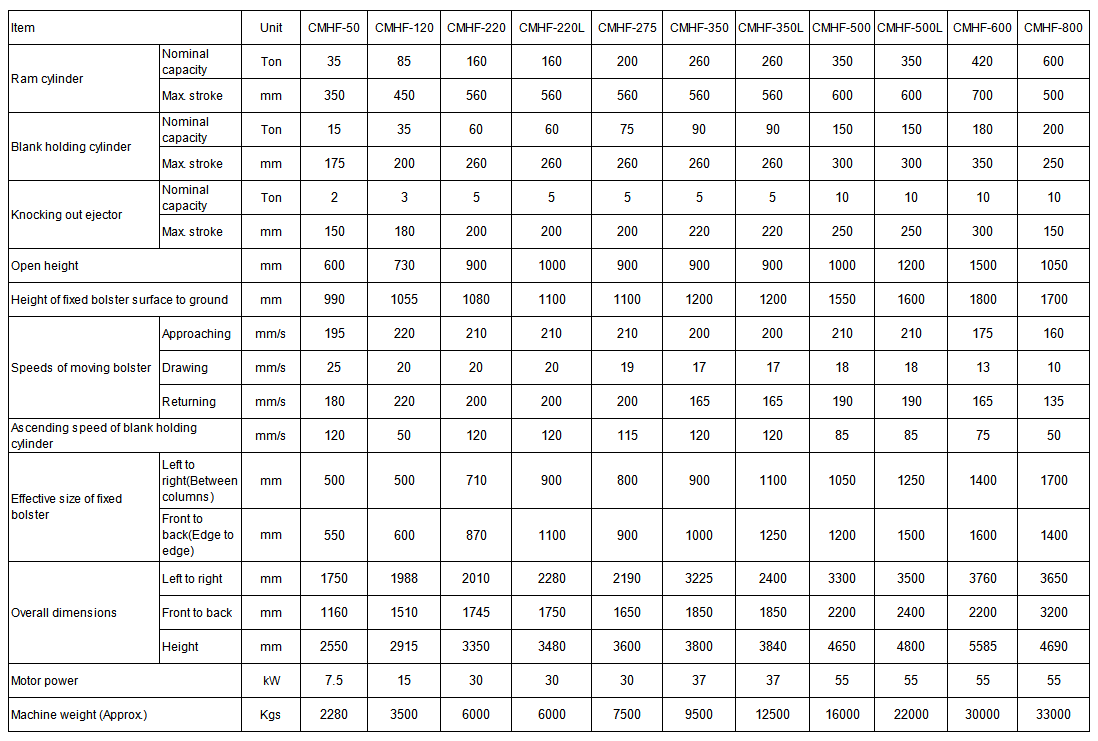

CMHF-Se Series Four Column Double Action Servo Driven Hydraulic Press

Application

Deep drawing, forming, stamping and trimming of metallic and non-metallic material such as tableware, kitchenware, metal cover of electric motor, fan, household appliances and lighting, etc.

Features

Ease operation: user friendly HMI, ease for setting parameters and recipe storage;

Control system: PLC + HMI (Siemens brand);

Pressing adjustment: high speed pressing setting, fulfill different pressing process technology requirement;

Accuracy monitoring: used for linear scale and pressure sensor to monitor the position and pressure, enhance the pressing accuracy;

Position accuracy: repeatability of ram position achieve to ±0.02mm, control the scrap rate of products caused by machine accuracy;

Pressing accuracy: repeatability of ram pressure achieve to ±3%, control the scrap rate of products caused by machine accuracy;

Machine structure: through finite element analysis, guarantee the strength and rigidity of hydraulic press;

Energy saving: high power motor fulfill high speed high pressure processing requirement, servo motor driving system can achieve energy saving 30 – 50%;

Low noise level: used of servo motor driving system, fulfill different speed and pressure of pressing requirement, ensures the stability of movement, lower noise level;

Ram cylinder designed: used of cast steel and its inner surface is finely grinded, prolonging working life under high pressure;

Knock-out cylinder: knock-out cylinder fixed inside of ram cylinder;

Hydraulic circuit designed: used of advance two-way cartridge valve, high reliability and less impact on changing of different pressing stage;

Performance of drawing process: changeable of ram and blank cylinders pressing force, can achieve 1 to 1 product forming, save the mold cost;

Automation: design of different automatic production equipment as customer requested;

(Induction motor driving system as option)

WeChat QR code

WeChat QR code Tiktok QR code

Tiktok QR code